Made Black completes its offer by adding to the main techniques different functional solutions to obtain the most varied decorative effects. We offer our customers Digital Printing, Sublimatic Printing, Pad Printing and Laser Printing, not only to make logos, but also and above all, special effects such as for example replicas of natural materials. Varnish and metals can thus be used to obtain an even wider range of effects, obviously always respecting the required performance requirements.

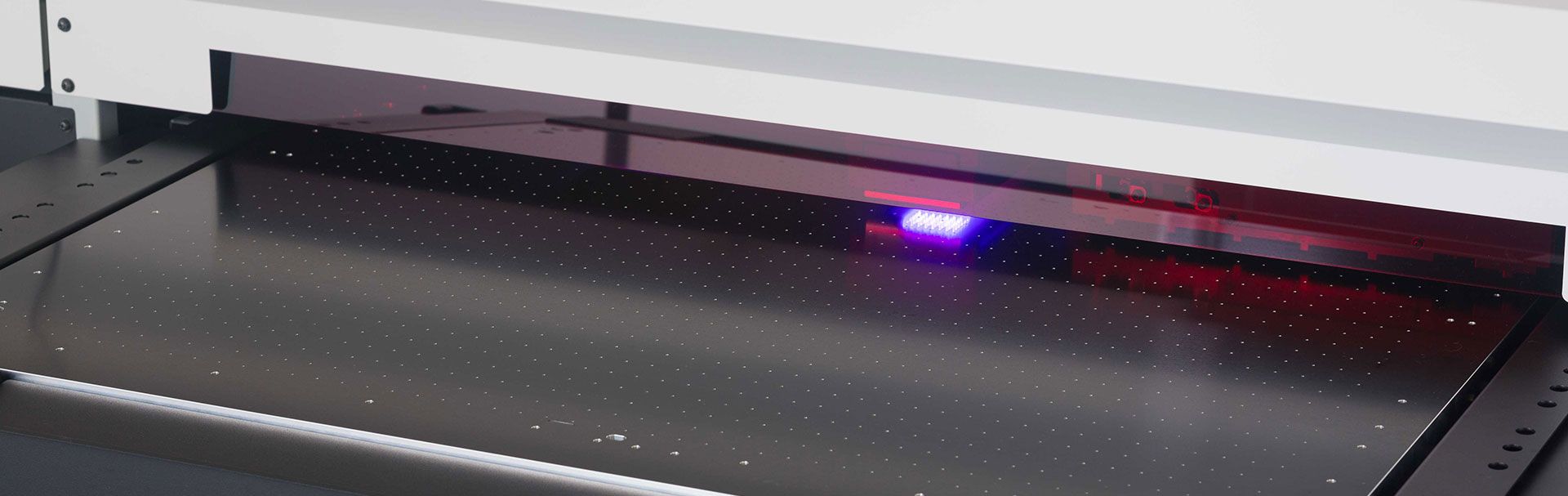

DIGITAL PRINTING - FREEDOM IN COLORS

Digital printing with ultraviolet technology makes it possible to directly print the surface of various small and large-format materials: from accessories to paper, wood-based cardboard, Plexiglas and many others - up to 15 cm thick. Similar to desktop or office inkjet desktop printers is possible to use special printers with special paints / inks to decorate a wide variety of objects, even with relief effects. A flexible solution, suitable for all relatively "flat" shapes.

SUBLIMATION PRINTING - DECORATIONS IN 3 DIMENSIONS

Sublimation printing (also known as "transfer" decoration) involves the printing of plastic film with the desired pattern (using other technologies, such as digital printing or screen printing), after which the article is adhered to the sheet (often, with the help of a vacuum chamber) and placed in an oven: here, thanks to the heat, the ink sublimates from the sheet onto the final product. Thus, it is often possible to realize seemingly impossible effects even on very complex three-dimensional shapes.

PAD PRINTING - THE MAXIMUM DEFINITION

Pad printing involves the use of a silicone pad to transfer ink to a flat or slightly three-dimensional surface (using the pad's ability to form around the product).

Obviously each addition of color must add a step, however, thanks to the remarkable definition of marking and high productivity, pad printing is often the technique of adoption to create logos or other geometric shapes.

LASER MARKING

Laser machines, CO2 or fiber, can be used to engrave products on the substrate, but also on painted surfaces.

For example it is possible to engrave the paint to show the shiny metal surface underneath and thus obtain logos or other decorations. Or it is possible to partially engrave the black paint to reveal a white layer and bring out a logo for contrast. Or you can simply turn the color of the paint to selectively create a pattern.